|

HI TECH GROUP was born from the will to

supply a full range of products to be able to satisfy

any requirements in the wood working sector, either in the

aluminum, plastic, light alloys and other ones. Each Company of the

Group offers specialized and reliable “made in

Italy” solutions.

The high technological level, on the reliability of

generations’ experiences , allowed a good

collaboration with customers leader in the world.

We are able to offer a very important products’ selection

starting from the advanced artisan up to the big company:

1-

Horizontal Beam Saws and turn key Sizing Plants

by Macmazza, to reach perfect size (cut quality to

be edge-banded directly and decimal

tolerance) of panels in wood or similar,

cross cut post forming/ pre-edged lines, thin fibers, HPL, high

thickness honey comb, lines for profiles/ solid strips, but also

plastic, aluminum, fiber cement, plasterboard, every panel material in

any different size, thickness and resistance

.

Any level of Automation/ handling, Managing Software and

Optimization of scraps, necessary in full projects engineered also with

space/ lay out analysis and solutions.

These Turn Key full plants can be demonstrated all over the world also

with the most customized solutions and working on three shifts a day,

but somewhere still working after 40 years of reliable life. |

|

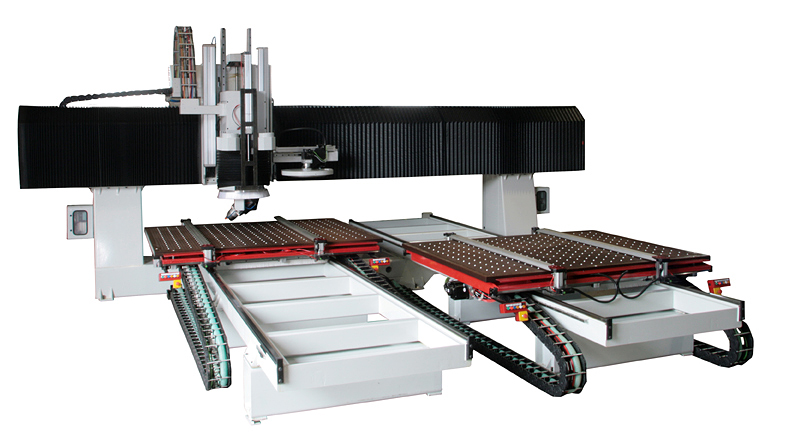

2-

CNC machining centres. Over the years

and thanks to their design versatility we've been able to

specialize in high technology machinery suitable for routing, drilling,

polishing, cutting and engraving works on wood as well as on composite

and plastic materials and light alloys. The wide product range

available today allows to meet all requests in the marketplace.

Automatic multiripsaws. Over 50 years has guaranteed not only

the well –known reliability, stability and sturdiness of this

product but it has also has focused its attention on safety and

user-friendliness.

|

|

3-

Drilling

machines operating for more than 100 years on mechanical field and from

ever positioned among the leader companies inside the reference market.

High is the engagement and projecting of new solutions to comply with

quality standard and production performances required by our customers,

putting at their disposal a sales and technical assistance qualified

staff employing updated systems based on CAD3D.

Our customers are companies operating in the furniture, doors and

windows field to whom we offer dedicated solutions for operations with

chip removal and for “tooling” insertion.

Special equipments are also foreseen for the working of plastic and

light metals, while we plan and manufacture systems to be paired to

operating machines to execute in automatic the loading, moving,

stacking and unloading of panels, thus creating completely automatic

working lines.

|

|

4-

Complete

solutions of calibrating-sanding and surface finishing,

production includes a wide range of machines for

the processing of various kinds of surfaces , from calibrating machines

, destinated to high performance levels of material removal , up to the

fine sanding machines for the surface and laquer finishing and

polishing operations , with a high added value.

The countless choices of possible compositions , the engineering

capacity to adapt the product to a multiple range of

solutions , the high solidity of the supporting structure and

the precision and meticulousness of each single component are

strong arguments which are making the ideal instrument needed

to obtain the total quality of the

processed products.

|

|

5-

The operation of the clamp is electric-pneumatic for the most economic

series, with motor brushless for the series to high

performance.

Both the solutions can be positioned in automatic lines of production,

they can also be positioned in lines of preparation and personalization

and to lines of completion and packaging lines with relative softwares

of supervision and connection to the server of the client, for receipt

with exchange data and to follow the product.

Thanks to the notable acquired specialization, we are able to

realize automatic fittingses of assemblage for furniture, stores for

subject first stores for worked seeds, automatic stores of consignment,

logistics of piles and individual panel on you install of workmanship

integrated with the cars of workmanship as drilling machines, inserting

devices, edge bonding machines, sizing machines, etc.

|

|

6-

Painting machinery

|

|

7-

Presse.

|

|

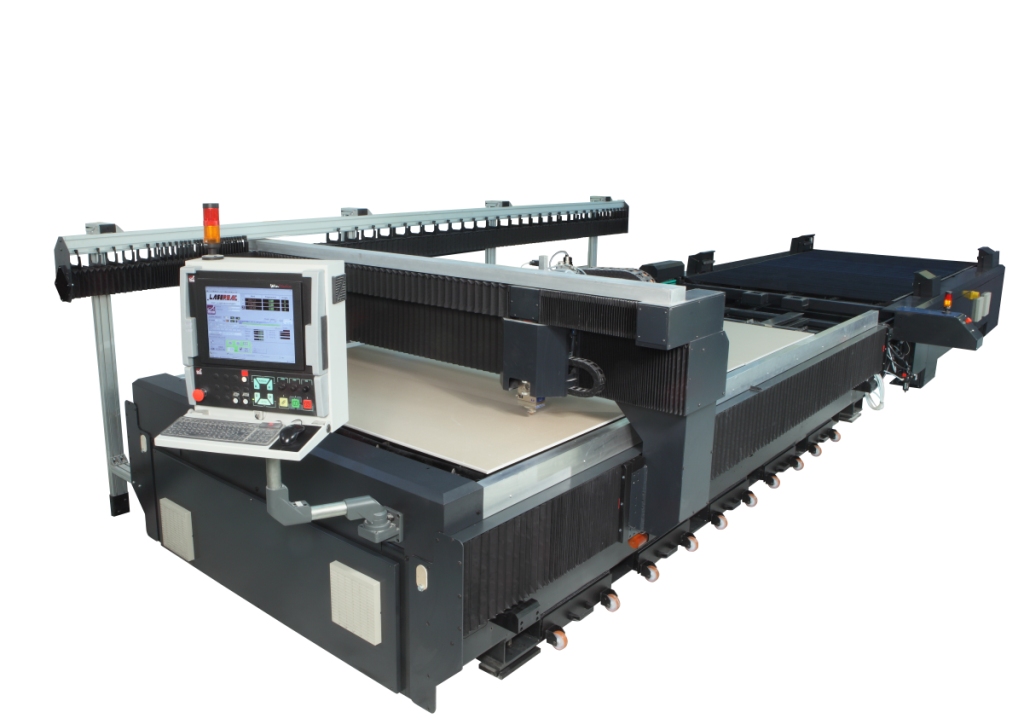

8-

CNC laser.

|

|

Any line of product can be supplied as stand alone machine

or as integrating part of a whole manufacturing process

installation equipped with its relevant automation system and

operational/label printing software for the complete organization of

the production cycle.

The chosen solutions are followed by Engineering Services and

operational Software to optimize the efficiency and the productivity of

any specific project.

HI TECH GROUP, from now intends to analyze

any self-employed valid and experienced

professional figures, being able to supply Commercial

Assistance and a proper before and after Sales

Service to our products.

Taking advantage from the synergic strength given by several

and complementary, specialized brands,

the target of this initiative is to improve the reached

performances by any individual company in their specialized sector,

without the need of grouping all the products together in exclusive and

mutual channels in case a strengthened commercial

network in any of the companies of the Group is

already existing.

HI TECH GROUP will show the full

range of their products at Xylexpo 2012 exhibition space in

Milan.

All the Companies of the Group will be awaiting to receive

your kind requests and simple curiosities to analyze new

interesting opportunities of collaboration.

Yours Sincerely

COMMERCIAL DIRECTION:

Alberto

Storoni |

|